At the request of a major bucket manufacturer, we have developed a regranulate that is made entirely from recycled plastic waste, which the bucket manufacturer turns into a paint bucket for a national chain of construction markets.

A successful product development with an innovative customer.

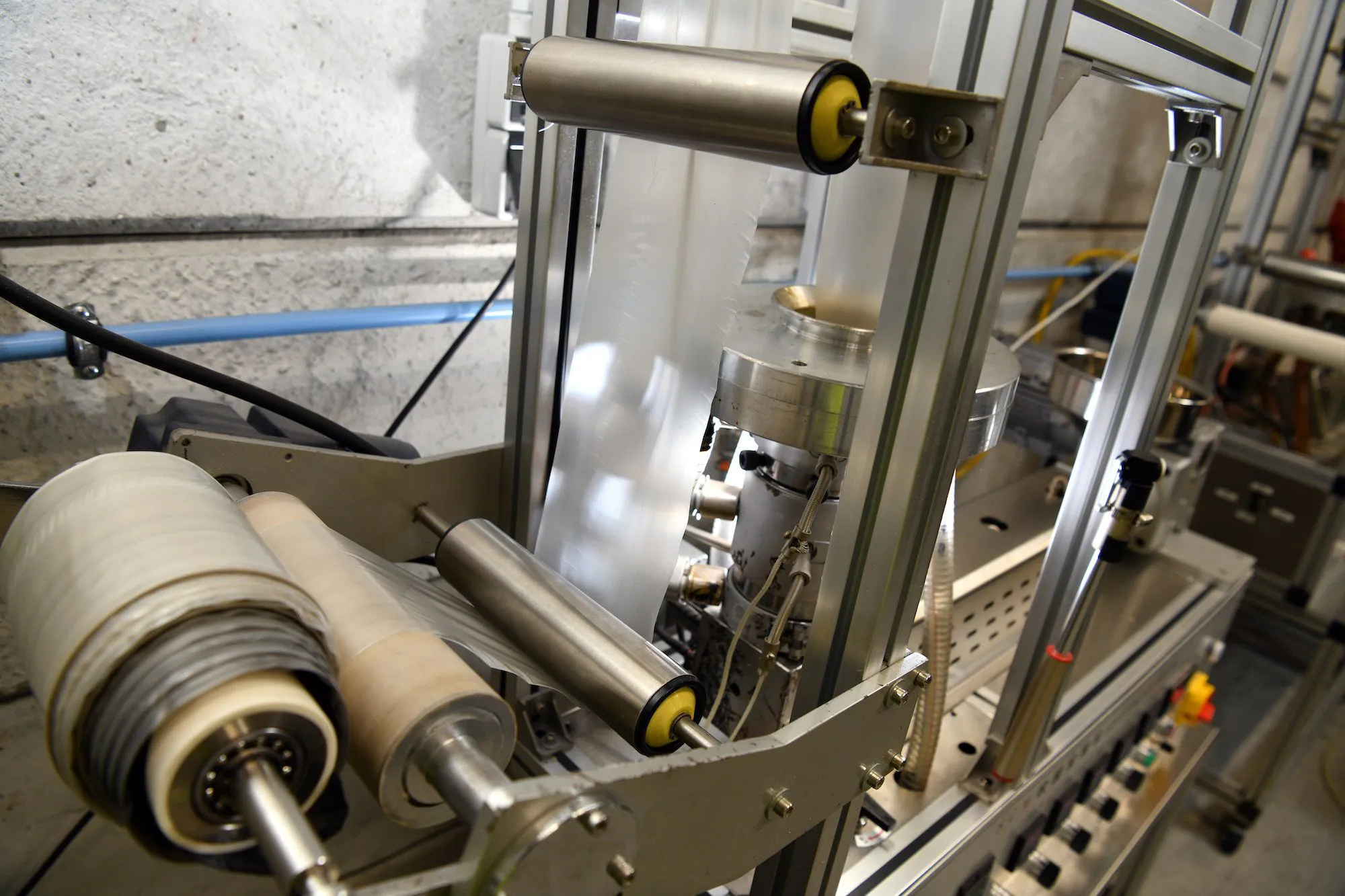

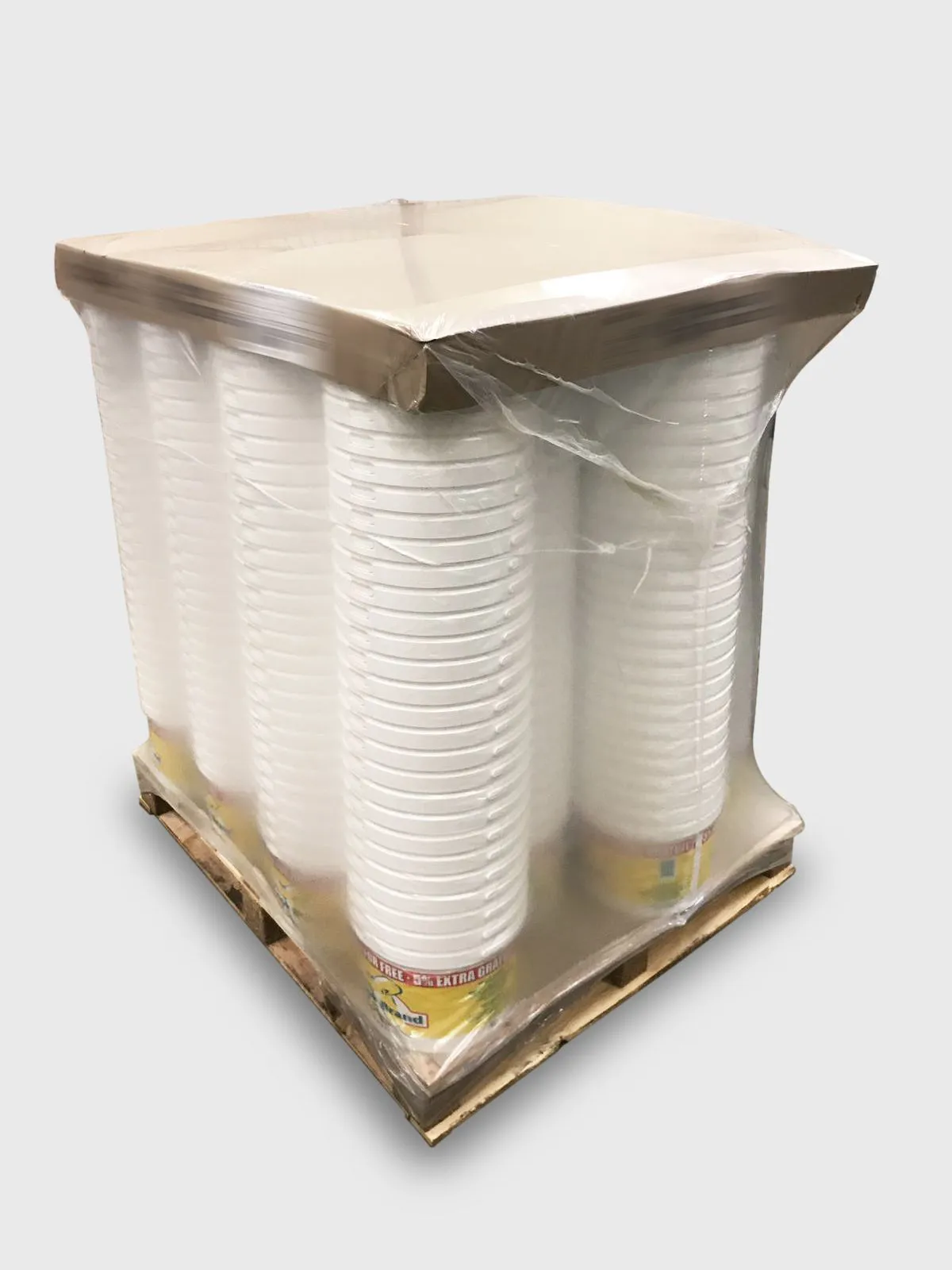

Until recently, shrink covers were made exclusively from 100% virgin (= new) material. We thought it should be possible to do it otherwise.

We started working on this and developed a regranulate from waste shrink covers that can serve as the basis for new shrink covers. The result is so good that the shrink covers made of 100% regranulate meet the quality requirements.

At the request of a large crate producer, we have developed a regranulate that is made entirely from recycled plastic waste from which they can produce crates for for example beer and soft drinks. This was an extra challenge for the lab because they had to develop a regranulate that is extra strong and durable.

The crates must be able to withstand quite a bit of weight, be able to be used multiple times and be robust. Together with the producer, we have succeeded in developing the suitable regranulate and producing it successfully.